Intelligent Prefabricated Substation (up to 40.5KV)

The prefabricated substation is also known as combined substation, box-type substation and outdoor substation. It is flexible, pollution-free, maintenance-free, convenient to transport and install. It also provides numerous advantages such as short construction period and low operating cost. As a new kind of power equipment, this distribution type substation is smart and standardized, which contributes to an around 12% decrease in floor area, a 10%-15% decrease in total investment and a half reduction in construction period.

Structural Features

Robust and reliable structure

The supporting frame is made of high-strength steel sections (H beam, I beam, channel steel and angle iron), which ensures strong resistance to wind and earthquake. This substation is overlapped and consists of box-type rock wool wall cladding, interior panel, steel structure, low-thickness square tube and other materials. All splice joints are sealed with waterproof glue. The fireproof interior panel can guarantee a nice exterior and high safety inside the box. Double-layered rock wool panel is excellent in thermal insulation. The air layer between two rock wool plates can protect this product from sound and heat. The roof drainage system is flexible, waterproof and can work smoothly.

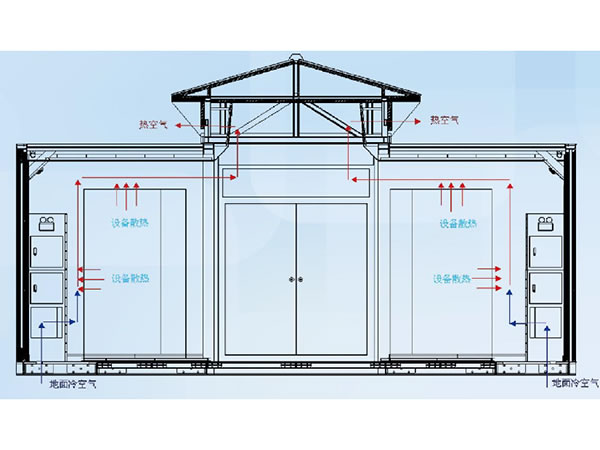

Air tightness and ventilation

According to the heat pressing and natural ventilation principle, our air vents can be optimized to offer the highest IP rating and the minimum coefficient of local resistance. The position and area of air vents can be determined by means of the calculation method under the overall ventilation rate.

Partial view of interior

The prefabricated chamber comes with multi-purpose switchgear, DC screen, network screen and arc-suppression coil control screen (as per customer requirements and engineering needs). It is also designed with lighting box, maintenance box, firefighting box and video box. This product can be used for lighting control, repair work and firefighting applications. It is equipped with a multitude of fans at four corners. The top of the chamber is also provided with numerous fans and air conditioners. The quantity of fans and air conditioners depends on the chamber size and equipment conditions. Ventilation and room temperature adjustment are available inside the chamber.

Equipment Selection and Description

The YBC-12 type 12kv smart prefabricated substation can be optionally configured with KYN28A-12 metal-clad removable AC metal-enclosed switch.

The KYN28A-12 metal-clad removable AC metal-enclosed switchgear is our in-house produced equipment. It is well suited for 3.6-12kv, three-phase-current, 50HZ single busbar system. This product is ideal for indoor applications. It has the capability to receive and distribute electric energy.

The cabinet body is constructed from aluminum-zinc alloy coated steel sheets, which results in strong corrosion resistance and high practicability. Additionally, our components must undergo multiple bending procedures for greatly improved strength. We use the same material that the cabinet body is made from for ease of purchase and production arrangement.

This cabinet can be optionally configured with VS1, VD4, ZN65A-EP and a variety of other circuit breakers, which offers numerous benefits such as light weight, good rigidity and so forth.

Technical Parameter of the YBC-12 AC Metal-enclosed Switchgear

| Item | Unit | Parameter |

| Rated voltage | kV | 12 |

| Rated current | A | 1250/2500/3150/4000 |

| Rated current of the main busbar | A | 1250/2500/3150/4000 |

| 1min power-frequency withstand voltage | kV | 42 |

| Lightning impulse withstand voltage (peak) | kV | 75 |

| Rated frequency | Hz | 50 |

| Rated short-time thermal current (4s) | kV | 40 |

| Rated dynamic current | kA | 100 |

| Overall dimension (L X W X H) | mm | 1500x800(1000)x2300 |

The YBC-40.5 type 40.5kv smart prefabricated substation can work with XGN8-40.5 type charging cabinet. The XGN8-40.5 box type, gas insulated metal-enclosed switchgear is our in-house produced product. It works with C-G15 charging cabinet and is ideally suited for the 40.5KV, three phase current, 50Hz single busbar system. This product can be used to receive and distribute electric power. It performs control, protection, measurement, supervision and communication procedures under failures and normal operations of electric power systems.

Features

1. Highly adaptable to all kinds of severe environments, such as: dust, chemical, condensation, contaminant, highland, small animals, etc.

2. Small footprint

3. Exceptionally reliable and free from maintenance

4. Perfect mechanical safety interlocks

5. Can be configured with integrated smart control protection device

2. Technical Parameter of YBC-40.5 type Equipment

| Item | Unit | Parameter | ||

| Rated insulation level | Rated lightning impulse withstand voltage (peak) | Phase-to-ground, phase-to-phase |

kV | 185 |

| Isolation break | 215 | |||

| 1min Power frequency withstand voltage (Effective value) | Phase-to-ground, phase-to-phase |

95 | ||

| Isolation break | 118 | |||

| Auxiliary control circuit | Rated voltage | V | DC : 110,220 | |

| AC : 110,220 | ||||

| 1min Power frequency withstand voltage | 2000 | |||

| Rated pressure of SF6 gas (gage pressure at 20 ℃) | Mpa | 0.04 | ||

| Max. pressure of SF6 gas (gage pressure at 20 ℃) | Mpa | 0.06 | ||

| Rated current | A | 1250/1600/2500 | ||

| Rated voltage | kV | 40.5 | ||

| Rated frequency | Hz | 50 | ||

| Rated peak withstand current (peak) | kA | 80 | ||

| Rated short-circuit making current (peak) | kA | |||

| Rated short circuit breaking current (Effective value) | kA | 31.5 | ||

| Rated short-time withstand current (Effective value) | kA | |||

| Rated short time withstand duration (Effective value) | s | 4 | ||

Installation Project

Shorten the construction period to two weeks

The main facilities of the YBC substation are prefabricated and simply cabled on construction sites. After a conventional test is done, this substation will be delivered and put into production. The entire assembly process can be completed in two weeks.

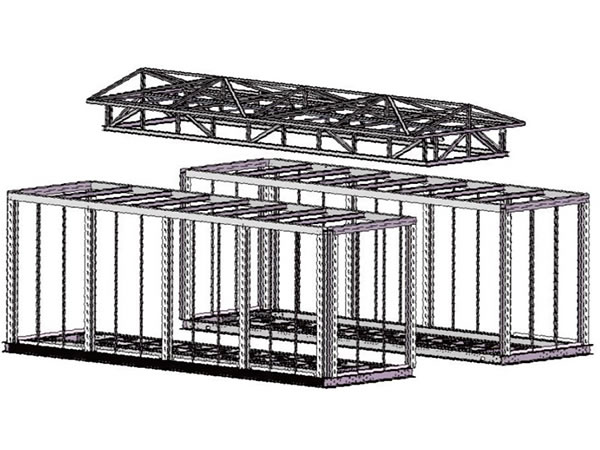

Prefabricated Assembly

The cabinet is multi-point bolted and multi-point welded.

The prefabricated chamber can be transported in whole or in parts, which depends on the chamber size and road condition during transport. All parts of the chamber come with top-mounted suspension points. This helps to prevent the chamber from scratches and impact. Meanwhile, this also ensures the position of the chamber when being lifted.

Hours of Splicing

The chamber can be accurately positioned with the use of roof suspension. The upper and lower beams are fixed with bolts to ensure a robust structure. Then, the roof cover is lifted and fixed. The entire assembly process is easy and fast.